Igwe ihe eji eme ihe nke PET dị elu

Njirimara

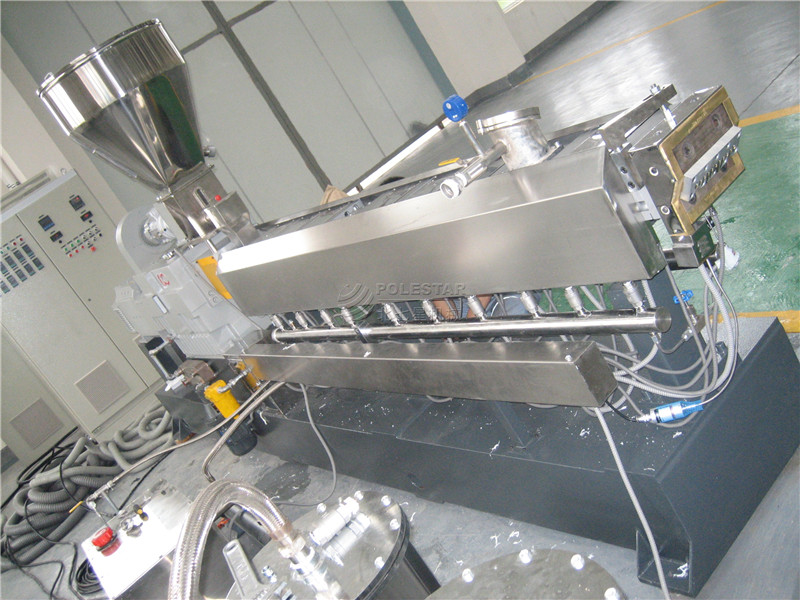

The PET pelletizer bụ tumadi esịnede ndị na-esonụ ngwá: extruder, haịdrọlik ihuenyo changer, strand ọnwụ ebu, jụrụ conveyor, draya, cutter, fan ịfụ usoro (nri na ihicha usoro), wdg Jiri yiri ejima ịghasa extruder nwere ezi okpomọkụ akara, elu mmepụta na ala ike oriri.

Ngwa

A na-eji igwe pelletizing anụ ụlọ na-eme ka PET plastic flakes n'ime pellet ma ọ bụ granule.Twin screw extruder recycling & pelletizing system na-etinye aka na ihe mkpofu, nke chọrọ nnukwu nhazi nhazi nke agbaze, volatilization, nzacha wdg.

Usoro Usoro

Screw feeder (Nhọrọ) → Force feeder → Parallel twin screw extruder →Hydraulic filter exchanger → Isi ebu → mmiri jụrụ oyi → Mpempe ọkọlọtọ plastic → Mkpọkọ ngwaahịa emechara.

Nkọwa zuru ezu nke ihe ọ bụla

1. Screw Feeder: bufee scraps plastik n'ime igwe isi.

2. Force feeder: nri ihe na-enye extruder na a haziri ọsọ, nwere ike gbanwee ọsọ.

3. Parallel ejima ịghasa extruder: plasticizing ihe na-agwụ ike gas.

4. Sistemụ mgbanwe netwọk dị elu na Die-head: nyocha adịghị ọcha, iji mee ka mmepụta kwụsie ike.

5. Mmiri mmiri: na-eme ka ọkpụkpụ PET dị jụụ.

6. Plastic ọkọlọtọ cutter: bee PET noodles n'ime granuels.

Uru asọmpi

1. Akpaaka PLC njikwa

2. Site na njikwa okpomọkụ nke onye ọ bụla

3. Ịrụ ọrụ dị mma & arụmọrụ Stable

4. Dị oke mma, nchebe gburugburu ebe obibi na nchekwa ike

Data teknụzụ

| Onye na-apụ apụ | TSK35 | TSK50 | TSK60 | TSK65 | TSK75 | TSK95 |

| L/D (mm) | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 |

| Ọsọ kacha (rpm) | 600 | 500 | 300-500 | 400-500 | 400-500 | 300-400 |

| Ike moto (kw) | 11-18.5 | 22-37 | 37-55 | 45-75 | 90-160 | 185-250 |

| Ike ikpo ọkụ (kw) | 16 | 24 | 30 | 34 | 45 | 60 |

| Nsonaazụ kacha (kg/h) | 20-80 | 50-200 | 80-300 | 100-350 | 200-500 | 700-1200 |

Ụdị ngwaahịa

Ịchọrọ ịgbakwunye Sky na nhazi gị?

Kpọtụrụ anyị taa maka ndụmọdụ imewe.