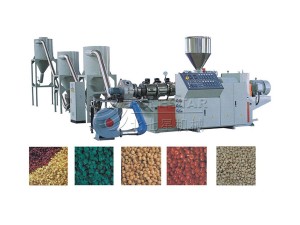

EVA TPR TPU Plastic Underwater Granulation Line

Nkọwa

Nke a granulation ahịrị bụ nke usoro nri (Screw metering feeder and Side feeding system), ejima ịghasa extruder, mmiri jụrụ oyi usoro, eletrọnịkị akara usoro na n'okpuru mmiri pelletizing usoro. Raw ihe: PP, HDPE, LDPE, LLDPE, TPV, EVA, ABS, PA na PS, wdg.

Ngwa

N'okpuru mmiri pelletizing ahịrị na-etinyere na PET + PE, Pee, PP n'efu flakes granulation field.Through extrusion, ịcha na akọrọ usoro, na n'efu karama ga-aghọ pellets.The pellets na-ọtụtụ-eji na plastic ụlọ ọrụ, dị ka mpempe akwụkwọ, na profaịlụ mmepụta.

Site na usoro nri na ngwaahịa ikpeazụ, anyị nwere ike ịmepụta ma rụọ ọrụ usoro zuru ezu iji mejuo ihe niile ị na-emepụta chọrọ. Anyị ga-enye gị usoro pelletizing dị mma na ọnụahịa dị ka ihe ị chọrọ.

Uru asọmpi

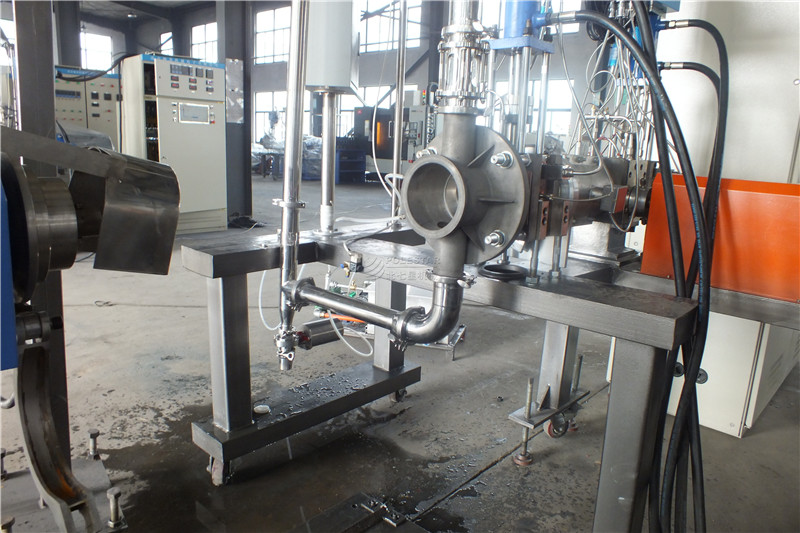

1. Superhard alloy anwụ isi (mere site anyị ụlọ ọrụ, nkwa serviceability afọ abụọ, ike ike iru HRC88-90, elu ka BKG ụlọ ọrụ)

2. Wearproof pụrụ iche alloy agụba (mere site anyị ụlọ ọrụ, ebuli oge dịkarịa ala otu afọ, hardness iru HRC70-75, elu ka BKG ụlọ ọrụ)

3. Pụrụ iche anwụ isi okpomọkụ akara ngwaọrụ (nke ụlọ ọrụ anyị mere, na-abụghị kọntaktị induction kpo oku, ikpo ọkụ ngwa ngwa, elu ka BKG ụlọ ọrụ na ndị ọzọ anụ ụlọ emepụta' electric kpo oku mkpara)

4. Pneumatic akara, na-akpaghị aka mgbanwe agụụ mma usoro (The mbụ patent ngwaahịa nke ụlọ ọrụ anyị, karịrị ndị ọzọ anụ ụlọ emepụta' mmiri akwụkwọ ntuziaka mgbali regulating usoro)

5. Otu-pịa buut (dị mfe ọrụ)

Polestar Machinery a ọkachamara factory maka n'ichepụta usoro mkpofu plastic recycling akụrụngwa (PET bottle recycling; PE / PP film, akpa imegharị ihe, HDPE karama / PP gbọmgbọm imegharị ihe, na PP PE film pelletizing, PP PE flakes pelletizing, PP / PE / PVC corrugated ọkpọkọ extruder wdg). Ọ bụrụ na ịchọrọ nkọwa ndị ọzọ nke igwe ịsa karama PET anyị / igwe ihe eji emegharị plastik / ahịrị pelletizing plastik, biko egbula oge ime ka m mara! Nabata na ụlọ ọrụ anyị!

Data teknụzụ

| Nlereanya | TSSK-30 | TSSK-35 | TSSK-50 | TSSK-65 | TSSK-75 | TSSK-95 |

| Dayameta ịghasa (mm) | 28.5 | 33.2 | 48.1 | 63 | 72 | 92 |

| Ọsọ rotary (rpm) | 400 | 400/600 | 500/600 | 400/500 | 400/500 | 400/500 |

| Isi moto ike(kw) | 11 | 11/15 | 37/45 | 55/75 | 90/110 | 220/250 |

| L/D (L/D) | 28-48 | 32-48 | 32-48 | 32-48 | 32-48 | 32-40 |

| Ike (kg/h) | 5-30 | 10-80 | 20-150 | 100-300 | 300-600 | 700-1000 |

Ụdị ngwaahịa

Ịchọrọ ịgbakwunye Sky na nhazi gị?

Kpọtụrụ anyị taa maka ndụmọdụ imewe.